IndustrySense

Digital Andon for modern manufacturing companiesOptimize production and increase efficiency by up to 20% with IndustrySense – a solution that improves fluidity and reduces work stress.

The benefits that IndustrySense brings to your production

What benefits does our solution bring?

Real-time OEE calculation

IndustrySense provides immediate insight into manufacturing efficiency and performance, helping managers make more informed decisions and effectively manage manufacturing processes.

Alerts with the Andon system

The digital Andon system in IndustrySense enables immediate response to problems, minimizes downtime and increases production flow through visual alerts.

Reducing stress in the workplace

Intuitive interfaces and accessible information reduce operator stress and simplify their work, promoting comfort and efficiency for the entire team.

Detailed records for audit

Every event and downtime is accurately recorded, supporting a thorough audit and compliance with quality and safety standards in your production.

Tailor-made modular functions

IndustrySense allows you to use only selected modules, such as fault reporting, OEE calculation or downtime display, exactly according to your needs.

Hardware support from Rubiq

Our partners at Rubiq Technologies will provide the necessary hardware installation and configuration for IndustrySense to function optimally in your operation.

Let's transform production together

We have already done this with these companies

Interfaces and functions designed for simple and efficient production

IndustrySense offers clear interfaces and key tools that make it easy to manage production, monitor downtime and support teams at every level.

Operator panel

Operators can easily report downtime, monitor OEE graphs, see production status and order details. This panel provides them with the information they need to effectively handle tasks without unnecessary stress.

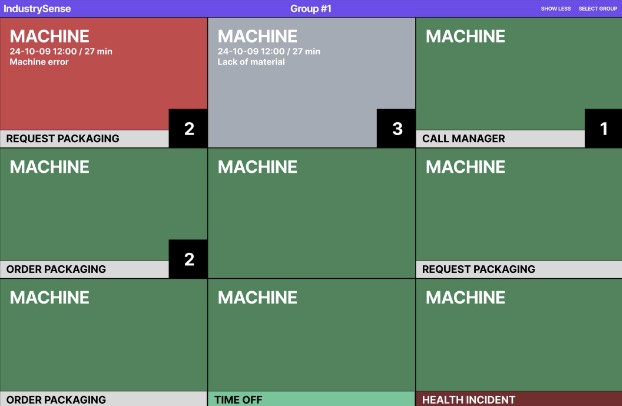

Digital Andon system

TV screens in production display the current status of several production lines in one place, enabling teams to quickly orientate and coordinate. The system thus significantly supports efficient production management and quick response to downtime.

Management Interface

It enables production planning, order management and line status monitoring, which provides managers with a detailed overview and tools for effective management of the production process.

Interface for Maintenance

It streamlines the planning and coordination of service interventions, which leads to the minimization of downtime and long-term reliability of the machines. The interface also includes predictive notifications for better monitoring of device status.

for efficient production processes

7

Locations

400+

Employees

IndustrySense grows with your needs and the future of manufacturing

Mobile application with QR code

The mobile application will allow employees to log in using a QR code, bring mobile notifications and offer a version adapted for direct use on the production line.

Predictive maintenance

Based on historical data, it enables planning of maintenance in advance and reduces the probability of unplanned shutdowns.

Integration with ERP, IoT and warehouse systems

Advanced integration options enable efficient connection to existing systems in production, contributing to fluidity and easy management.

Monitoring of energy consumption and emissions

It will enable the monitoring of energy efficiency and the reduction of the environmental impact of production.